What are the Shipping Container Dimensions & Specifications?

Shipping containers are held to very specific dimensional standards to ensure they can be safely stacked on top of, and below, any other shipping container in the world. Standard shipping containers are 8′ wide (2.44m), and are measured in TEU’s (twenty-foot equivalent units). Ocean cargo containers are held to a rigid standard to ensure that there are no issues during shipping.

Each intermodal shipping container (sometimes called “conex” containers) must be able to not only stack perfectly on a cargo ship, but also lock into chassis trailers safely and securely stack on rail cars. The International Organization for Standardization (ISO) sets the standards for shipping container dimensions

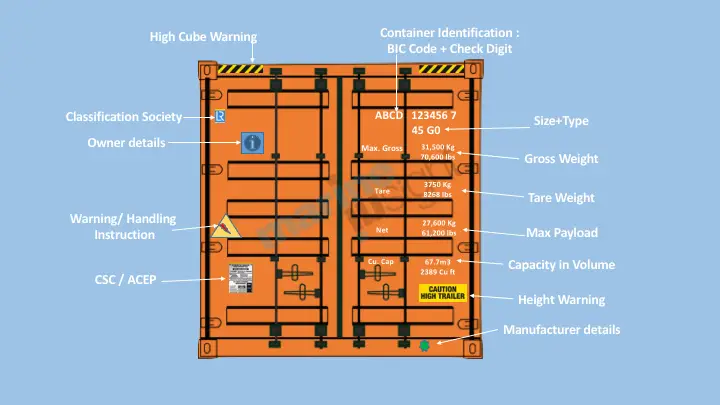

Markings on a shipping container

The standard for the coding, identification, and marking of containers is DIN EN ISO 6346, dated January 1996.

Following are the different markings provided in an ISO container.

Container Number

The container marking is the primary identification marking on the door end of an ISO container. It consists of seven numbers and four letters, which are allotted by the ISO to identify every container to its owner. The number is unique for everyone and is registered for the records with Bureau International des Containers (BIC), Paris.

Suppose the container number as shown in the diagram is-

ABCD 123456 7

Here the first 3 letters, i.e. ABC denotes- Code for the Owner of the container

The 4th letter D provides -the container category

The first six numbers, i.e. 123456 is – the serial numbers of the container

The last number, i.e. 7 is- the check digit which is used to validate if the owner or product group code and the registration number have been accurately transmitted.

Related Reading: How are shipping containers made?

Owner’s Logo

The shipping line or container vendor’s logo/name is provided on the end door.

ISO Code

The ISO container code is stencilled below the container identification number and provides the details of the type of container, i.e. GP (for general purpose), DV (for a dry van) etc. and also denote the size of the container. E.g. if the ISO code below the container identification number is 45 G0, the first number, i.e. “4” denotes the code length (40 ft) and the second number, i.e. “5” is the code for width. The last two alpha-numeric character shows the type and subtype of the ISO container.

Weights & Payload

All the details of container weight and cargo weight are also marked in the end door.

– The weight of the shipping container: The true weight of an empty container provided by the manufacturer post the manufacturing process.

– Payload: This is the maximum cargo weight an approved ISO container can carry

– Gross Weight: The total weight of container and cargo within the safe limit

Approved Classification society label

Before the container is used by a shipping company for cargo transfer; it is tested for seaworthiness and compliance with the ISO standards by an approved classification society. The label of the class is also provided on the end door of the container.

Related Reading: What is the international association of classification societies?

Cube or volume

The cubic capacity or the volume of the container is marked in the end door.

Warning and Operational Signs

The container may carry various warning labels and signs depending upon its type and cargo it is carrying. E.g. a heightened container will contain the height or warning stripes on the top part of the container. Similarly, a container carrying hazardous cargo will carry a warning sign about the type of hazard or cargo associated with it.

Related Reading: 8 Things Deck Officers Must Know While Handling Packaged IMDG Cargo

Certifications

Different certificates which are occupied by the container needs to be displayed using plates, such as:

CSC plate: Container Safety Convention plate showing the ISO container has been inspected and tested by approved authorities. It also contains details of the owners and other technical specifications.

ACEP: It stands for Approved Continuous Examination Programme and is provided in the container. This is a safety program for shipping containers, wherein the container under it has to undergo an extensive inspection in a container depot every 30 months of its service. The container owner will renew the ACEP every 10 years.

Related Reading: What is Container Security Initiative And How Does It Work?

For a seagoing professional or anyone who wants to transport cargo through shipping containers, it is very important to understand different shipping container dimensions, nomenclature, signals, symbols and signs displayed not only in various parts of the ship but in the cargo containers too.

If you think we missed some or should add more specifications related to the shipping container, please provide your valuable comment below.